The use of technology to make work easier in restaurant and catering kitchens has long been an indispensable fact of life, be it with combi-steamers, sous-vide cookers or automatic deep fryers.

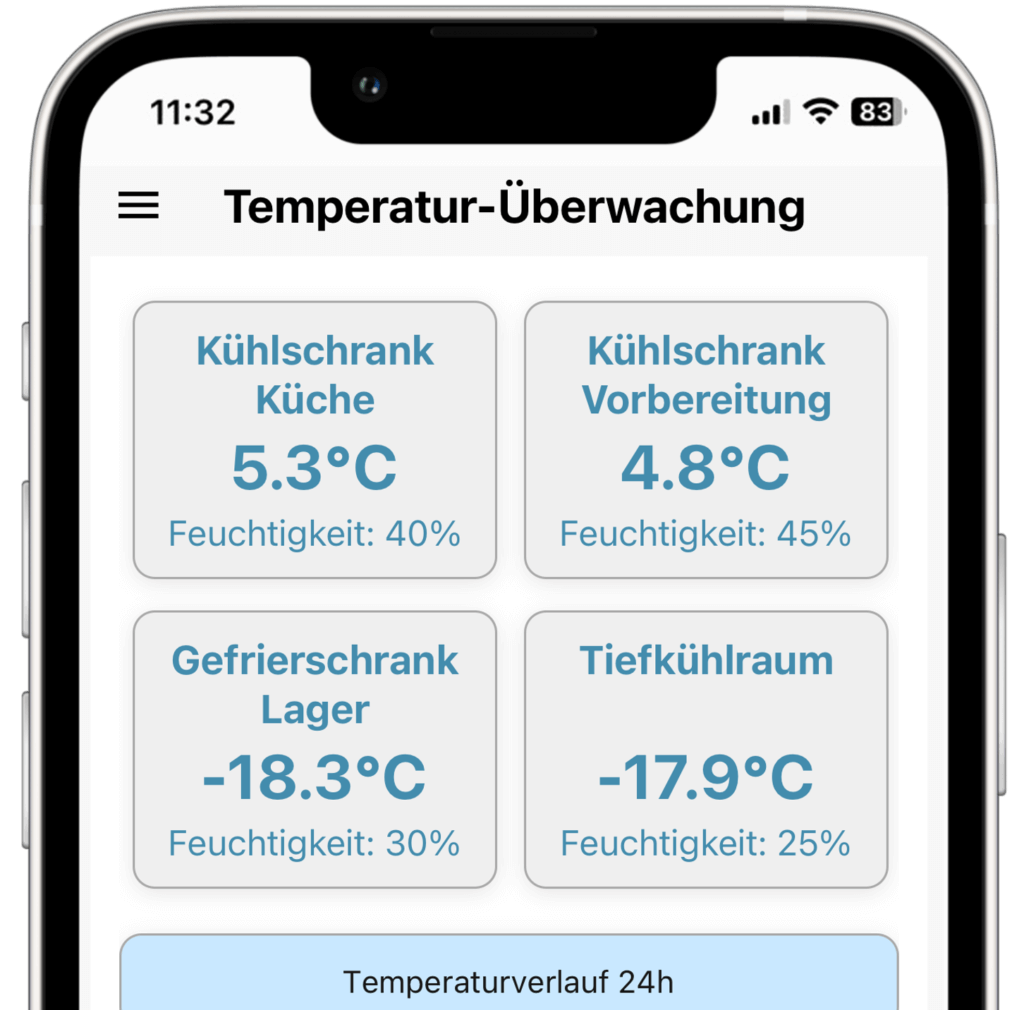

Since HACCP documentation can be done via smartphone and tablet, such as with the Alcomo HACCP Appthe automatic temperature recording of refrigeration and deep-freeze equipment has also become increasingly important.

What is already commonplace in the food industry is increasingly finding its way into restaurant and catering kitchens.

Why automatic temperature recording is important

Automatic temperature logging of refrigeration and deep-freeze equipment is an important step in ensuring food safety and compliance with HACCP (Hazard Analysis and Critical Control Points) requirements in the catering industry.

With our solution, we combine the advantages of modern sensor technology with the Alcomo HACCP app. By using IoT-based sensors that monitor and automatically record temperatures in real time, our customers benefit from numerous advantages compared to conventional manual measurement methods:

The 5 biggest advantages of our solution

1. Continuous monitoring

- Automated sensors enable seamless temperature monitoring – 24 hours a day, 7 days a week.

- Ensuring up-to-date and reliable data, even during irregular operating hours or staff shortages.

- Manual measurements, on the other hand, are often irregular and prone to error.

2. Early alerting in the event of deviations

- Alarm systems notify you immediately by e-mail or app notification in the event of temperature deviations.

- Quick intervention minimizes the risk of food loss.

- In contrast, problems with manual checks often only become apparent at the next inspection.

3. Automated documentation and traceability

- Digital recording of temperature data reduces the effort considerably.

- All data can be retrieved at any time and offers complete traceability.

- Perfect for food inspections or audits, as no error-prone handwritten records are required.

4. Optimization of operating processes

- Reduced workload for staff by eliminating manual recording and documentation.

- Increased efficiency, especially for businesses with many refrigeration and deep-freeze units.

- The time gained can be used for other important tasks.

5. Improved food safety and HACCP compliance

- Critical control points (CCPs) are continuously monitored and documented.

- Compliance with HACCP guidelines is made easier, the risk of deviations is minimized.

- The highest hygiene standards are ensured and food losses are reduced.

This systematic approach to monitoring the cold and deep-freeze chains is an essential part of modern food businesses and restaurants.

Conclusion

The switch to automatic temperature recording with sensors offers numerous advantages for the gastronomy sector and catering industry:

- Accuracy and reliability of temperature controls.

- Saving time and resources.

- Compliance with legal requirements and improvement of food safety.

This modern solution is a valuable investment for any catering business that values food safety and quality.

This innovative additional function is now available as an extension to the Alcomo HACCP app.

Further information:

Visit our website:

Alcomo HACCP App

Sensor integration